And now the other side is completely done. The only thing left is potting on the tops of the chips, and the chips themselves.

The epoxy has been removed off the tops of the chips, revealing that all 12 are made of just two types- 4558 dual op-amps and 4016 analog switches.

This is what I predicted I would find, and I wasn't disappointed.

Like before, this makes a HUGE mess. Pictures do not accurately convey just how much "stuff" you end up with afterwards. The floor is covered, and it flies

everywhere! It took around 20-30 minutes to clean the shop up after I finish depotting a board.

There were alot of those polystyrene capacitors on this board. I hate them- they melt really easily and get damaged if you are not very careful during the procedure.

I didn't kill a single one before I had a chance to test it, but removing them does 'em in. I will be replacing them with mylar caps which are much smaller but should

be just as good- this isn't a very critical app, and mylars are more than enough for the job.

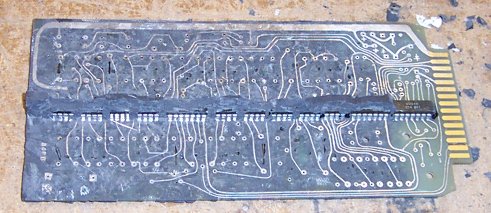

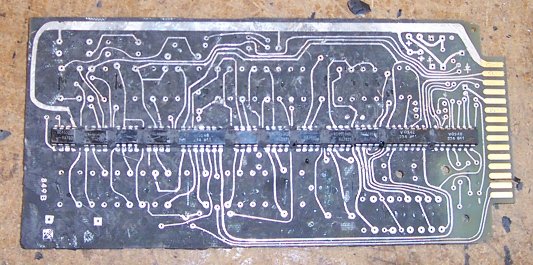

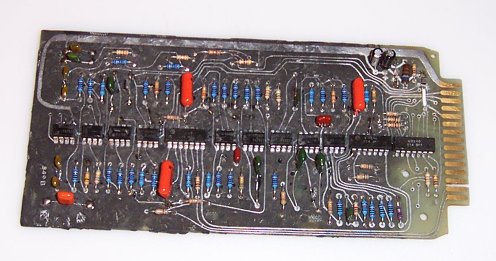

Top of the bare board after de-potting.

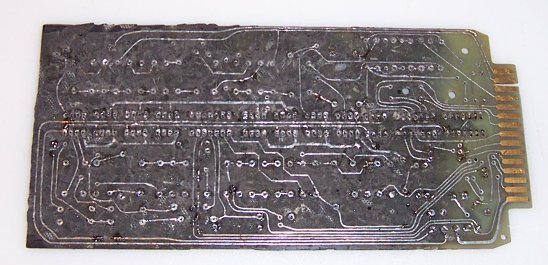

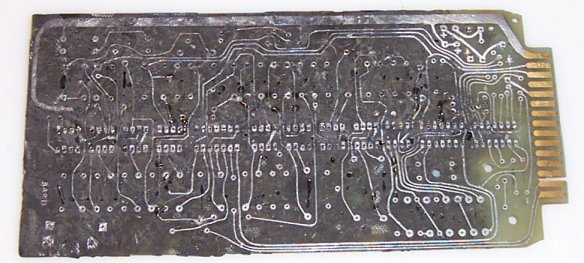

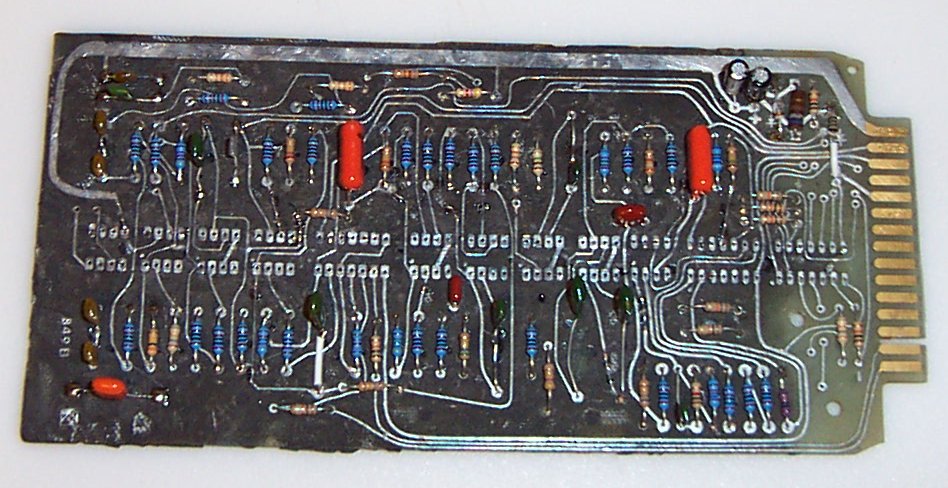

Bottom of the board.

Here's the parts that will be going back on the board.

These are the chips. Not a whole lot of chips on this board... it's mostly passives

to make up all those variable state filters.

The caps and resistors and diodes are on the board. At this point, I traced out the schematic

before putting the chips back on. This makes life 10x easier.

And now the chips are on the board. It has been tested and everything checks out.

Schematic of this board. (note: clicky for larger)

|